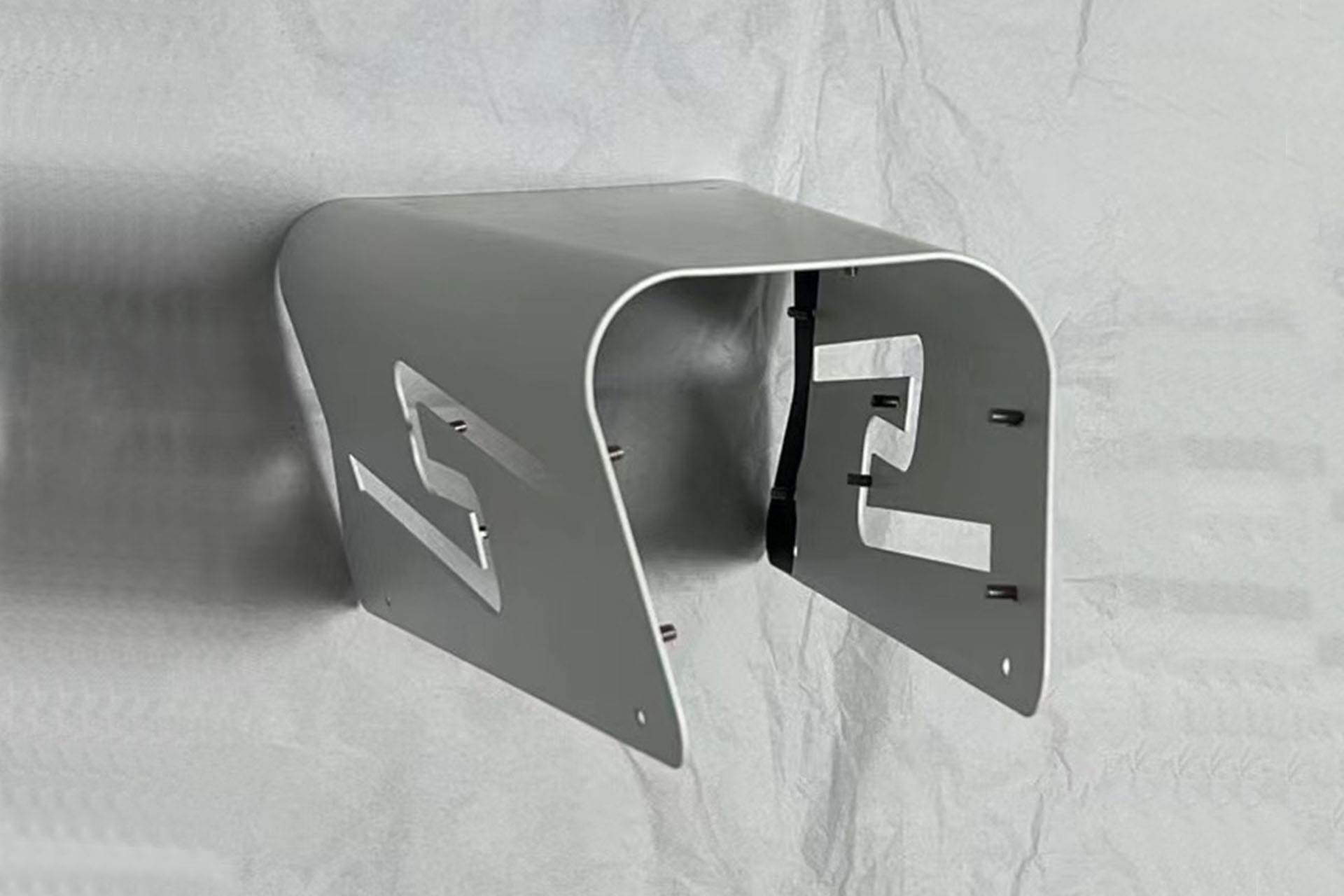

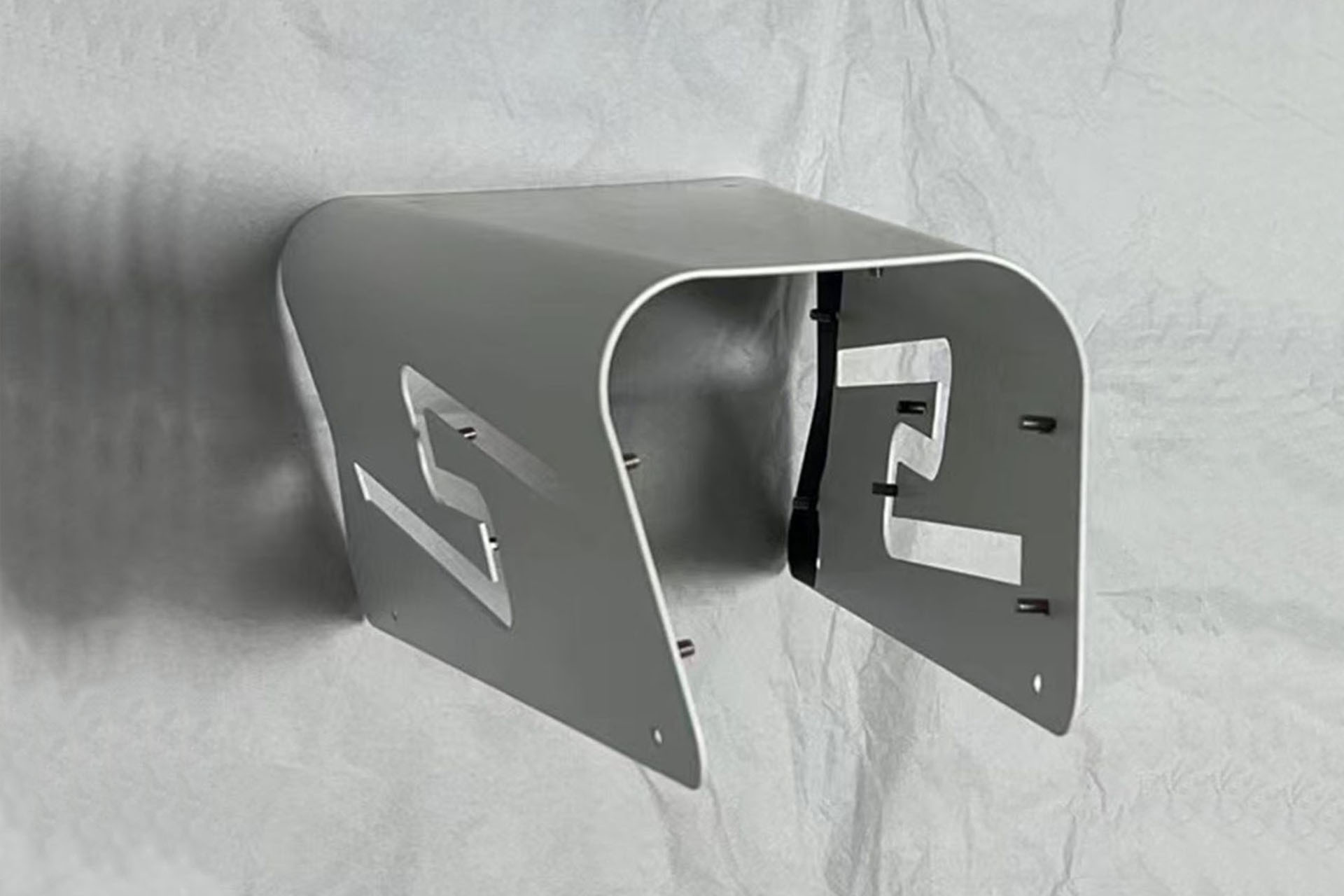

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a comprehensive cold working process for metal sheets (usually below 6mm), including shearing, punching, bending, welding, riveting, mold forming, and surface treatment. Its prominent feature is that the thickness of the same part is consistent.

Search

Search

Select Language

Select Language