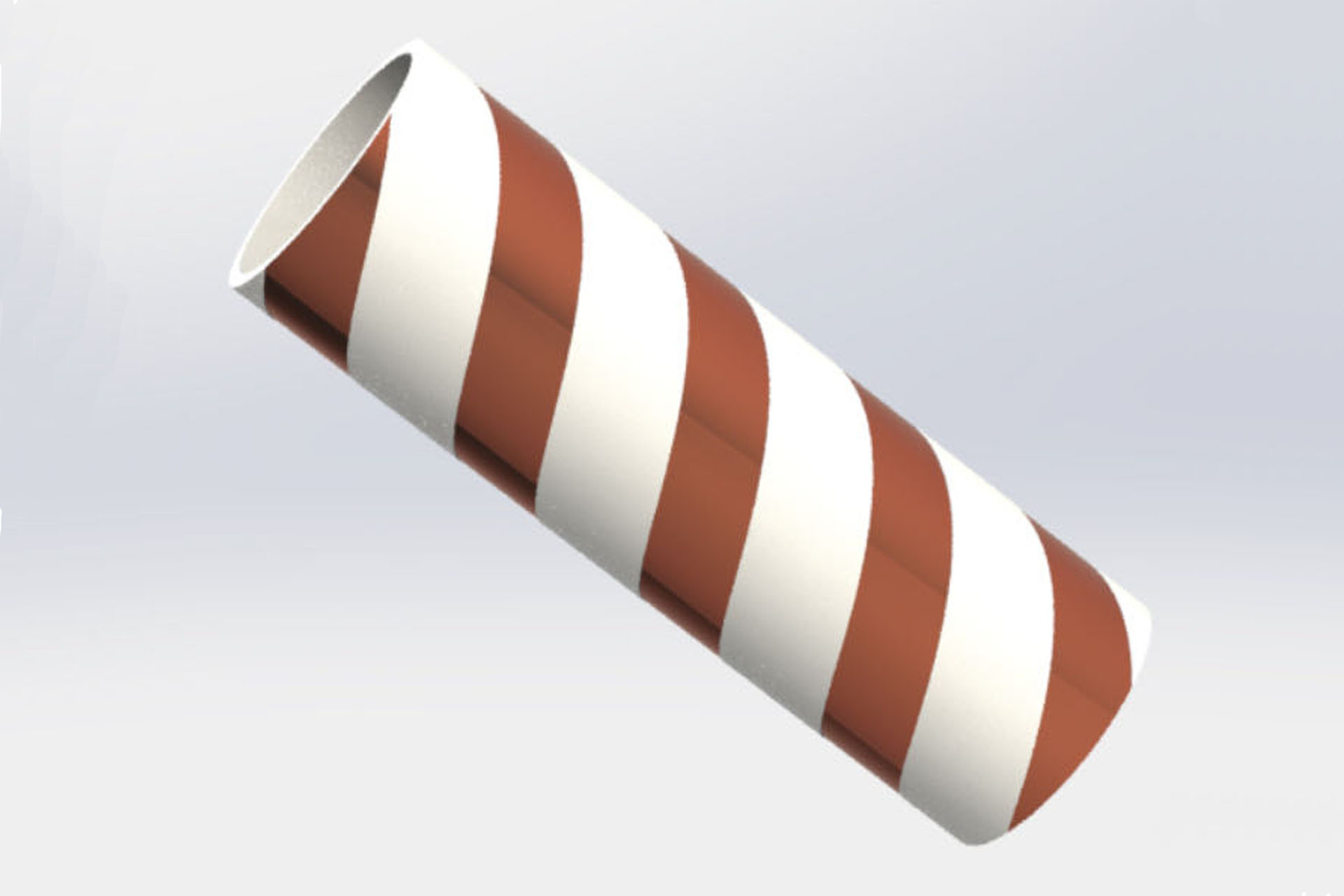

What Is Injection Molding?

Injection molding refers to a model with a certain shape, which is formed by injecting the melted colloid into the mold cavity through pressure.We have an experienced core technical team and provide various injection molding process services, such as feeding, plasticizing, injection, cooling, demolding, etc. You will receive highly professional manufacturing solutions and satisfactory process services.

Search

Search

Select Language

Select Language